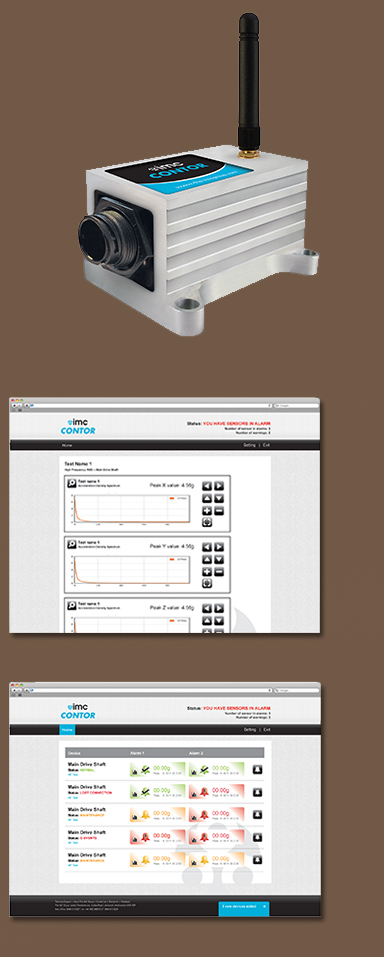

Contor uses tri-axial piezo accelerometers combined with ZigBee wireless communications and features include: robust hardware; real-time audible, visual and emailed alarms to relevant parties; comprehensive and user friendly software; ZigBee radio communication from unit to local receivers; and data stored in SQL database.

According to The IMC Group, the system significantly reduces machine downtime and has the ability to introduce predictive maintenance regimes - for example, bearings by monitoring the RMS vibration. Accurate data for warranty claims can be provided and maintenance costs reduced.

A typical use for the IMC Contor is with CNC machines. Using the spindle test routine, a quick test can be performed prior to operation to check the bearing condition and any abnormal vibration is immediately notified. Maintenance can be carried out before more damage occurs.

01462 688070sales@the-imcgroup.com