How have the demands placed on firefighters changed over the last few years?

Firefighters are now being called out to deal with new and increasingly complex threats due to a more complex industrial activity and changing urban landscape. This means that, aside from having to withstand the high temperatures of a fire, garments must also be designed and developed to protect the wearer in scenarios that include road traffic accidents, industrial clean up operations or flood rescues.

Electric arc is also a growing hazard in the industrial environment and can create a conducting plasma fireball with temperatures reaching upwards of 20,000 degrees centigrade. Arc flash injuries include external burns to the skin, internal burns from inhaling hot gasses and vaporised metal, hearing and eye damage.

Each of these scenarios carries its own set of risks and garments must therefore be adapted to offer multi-function protection to accommodate increasing demand for turnout gear to work harder and last longer.

How do these new risks affect garment design?

Whilst no PPE will ever provide complete protection against all firefighting risks, DuPont is constantly developing ways to improve turnout gear to reflect the changing roles and demands of the modern firefighter. We rigorously test each of our garment solutions to ensure high standards of safety not only in the fighting of fires but also when exposed to the rigours of day-to-day wear.

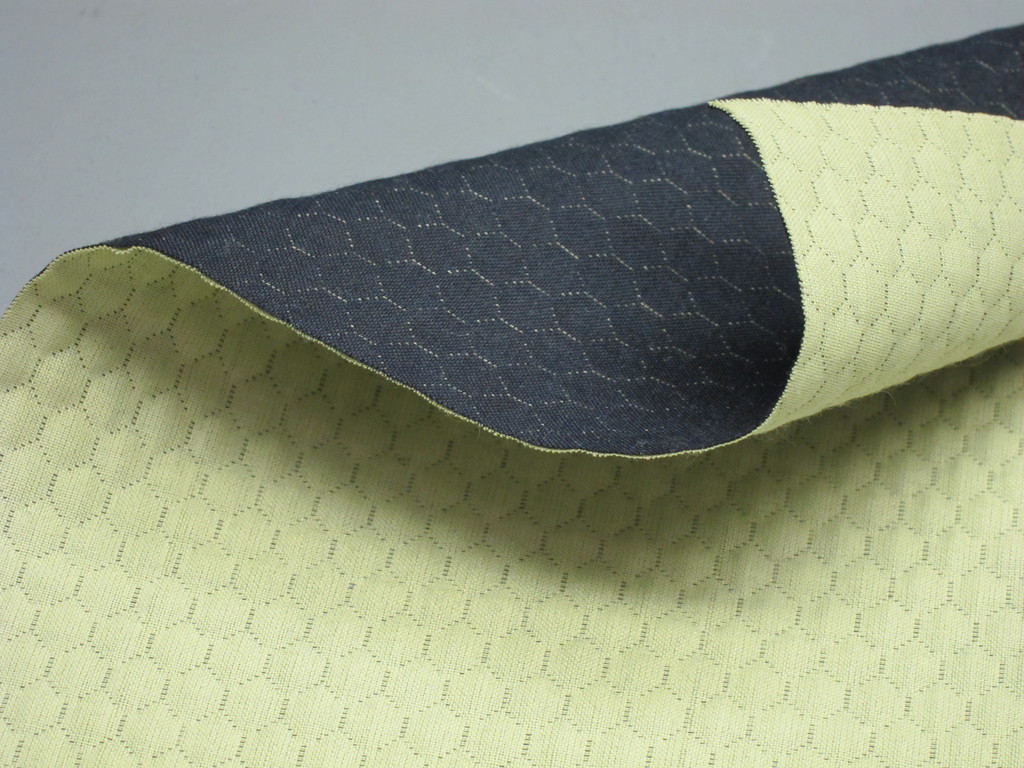

As a result of growing demand for turnout gear that offers both high levels of protection and comfort for the wearer, DuPont has developed a new outer shell fabric, DuPont Nomex 3DP. This incorporates new patented Intelligent Flux Technology, which comprises two layers of fabric woven together, an inner layer of DuPont Kevlar with an outer layer of DuPont Nomex.

When subjected to intense heat, the outer layer of DuPont Nomex thickens instantly and creates an expanded insulation barrier, reducing heat transfer and providing the firefighter with extra seconds of safety. This is supported by an inner layer of DuPont Kevlar which offers high mechanical strength. The intelligent weaving structure of DuPont Nomex 3DP also offers the wearer outstanding electric arc protection, high levels of comfort, flexibility and protection while also optimising durability. Incorporating this new technology within firefighter garments means that they can to be confident they have the time to respond to an incident safely, whatever the scenario.

How has the fabric technology been received by firefighters?

We recently tested DuPont Nomex 3DP at a facility in Germany and invited fire and rescue services to witness the results on DuPont Thermo-Man using the industry standard eight second flame impingement test. Firefighters were particularly impressed when comparing DuPont Nomex 3DP to other garment solutions on the market. These typically present a burn prediction of around 2% however, DuPont Nomex 3DP achieved an impressive zero burn prediction on all sets of turnout gear tested. It also qualified for outstanding ATPV results of 18cal/cm2 against electric arc hazards. These results, alongside a remarkable absence of garment damage, highlight the quality and high level of protection offered to wearers.

To ensure that DuPont Nomex 3DP can withstand the rigours of everyday firefighting, it has also been tested in the field by five brigades across Germany, France and Belgium. We received very positive feedback particularly around the enhanced comfort resulting from exceptional ease of movement in the garment, as well as its high mechanical strength and premium level of heat protection.

So is heat stress still an issue for firefighters?

Heat stress remains the number one cause of injuries and fatalities among firefighters despite significant advances in technology. Essentially, heat stress is caused by the body’s core temperature rising as a result of being exposed to heat and physical exertion. While sweat glands work to keep the body cool garments with high heat insulating properties, such as those worn by firefighters, can prevent sweat from evaporating and drawing heat away from the body. If a firefighter’s core body temperature rises too much, this can lead to impaired judgment and accidents.

We understand that the same garment that protects firefighters must also allow for the release of heat. DuPont works closely with firefighters to develop optimum fibre blends and fabric solutions to keen them safe, such as the new DuPont Nomex 3DP which offers high air permeability. However, the nature of a firefighter’s job ultimately means that issues such as heat stress will always pose a risk.