The internal tool and external tool are designed to eliminate the need for stocking taps and dies in the hope that one will fit a maintenance issue arising from damaged threads.

Damar’s managing director Brian Martin explained, "There is nothing more annoying and productivity zapping than a damaged threaded fastener. The NES internal and external tools make short work of fixing these problems to keep productivity high at all times. They are a small investment that easily pay for themselves many times over.”

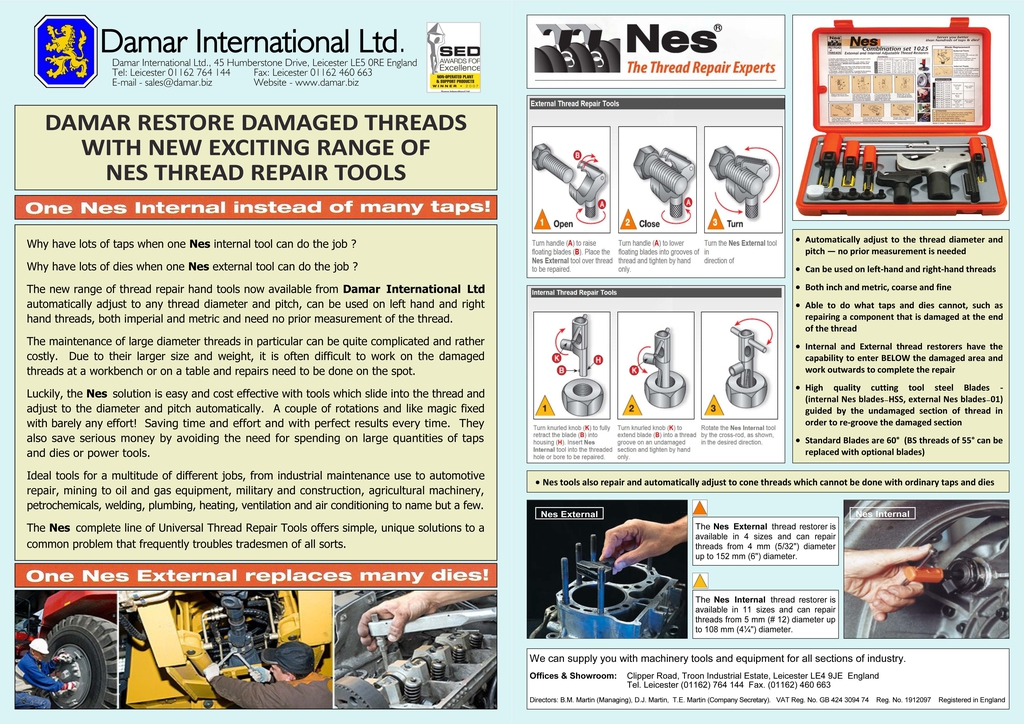

The new range of thread repair hand tools automatically adjust to any thread diameter and pitch, can be used on left hand and right hand threads, both imperial and metric and need no prior measurement of the thread.

A good example of the NES tool in action is the maintenance of large diameter threads which is often challenging and costly.

Large size and weight make it difficult to work on the damaged threads at a workbench so repairs need to be done on the spot. The NES thread repair tool deals with this problem easily, quickly and cost effectively. The NES slides into the thread and adjusts to the diameter and pitch automatically. A couple of rotations and like magic the thread is fixed with barely any effort.

The NES tools can also repair threads where ordinary taps and dies would fail. These include cone threads, components that are damaged at the end of the thread and the tool can enter below a damaged area and work outwards to complete a repair.

"From individual tradespeople to fully staffed industrial maintenance crews, the NES will prove itself the most useful hand tool to reach for when faced with a damaged thread of any diameter – internal or external. When downtime is so damaging to profitability, these tools are worth their weight in gold,” concluded Brian.

01162 764144sales@damar.biz