Kelly Rose

Editor

Kelly Rose

Editor

HILTON BODILL Construction contacted Fibrelite on behalf of their client, Nottingham City Hospital, who required a lightweight and strong modular covering system for their newly re-routed service trench, which replaced the traditional heavy concrete slabs.

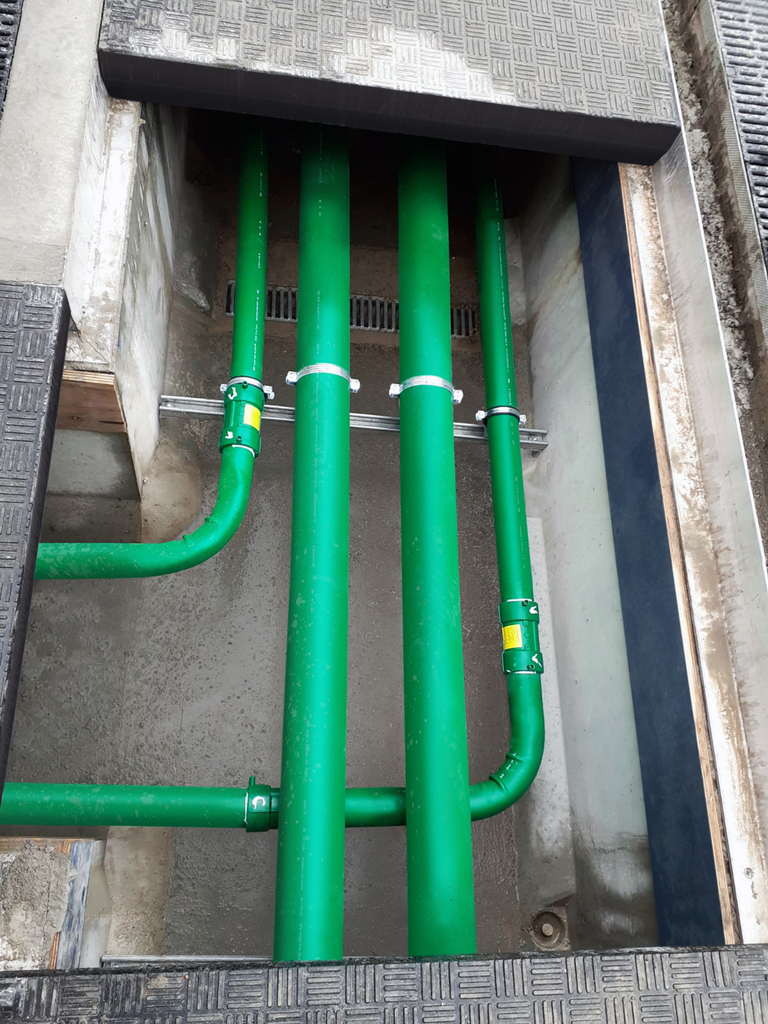

These protect and provide access to the hospital’s backup diesel generators supply pipes (diesel and oxygen). An easy-install, corrosion-free replacement for their previously existing steel piping was also required.

Problem

The previously existing concrete trench access covers were heavy, requiring specialist lifting equipment to remove and replace them: a time consuming and expensive process. Due to their weight, they also posed a risk of injury to maintenance teams (quick access to the piping is vital for maintenance and inspection). Nottingham City Hospital also wanted to replace their steel pipework with a reliable plastic piping system, eliminating the potential for corrosion and subsequent fluid egress.

Key issues with the previously existing products:

Concrete Access Covers

Heavy concrete access covers posed a risk of injury to maintenance teams and required specialist personnel/machinery for removal and replacement

Concrete covers often fracture and chip over time

Some covers would need to be modified to accommodate pipework extending from within the trench to above ground networks

Steel Pipework

Steel pipework can corrode over time, resulting in fluid egress (leaks)

The traditional steel pipework was heavy and labour intensive to work with

Solution

OPW’s UK technical team put together a proposal combining lightweight Fibrelite GRP composite trench covers and KPS double wall polyethylene piping, which was accepted by the contractor and end user.

Key Benefits Of Fibrelite Covers For This Project:

No specialist machinery or personnel required for removal and replacement

Strength-to-weight ratio. All trench covers can be safely removed manually by two people while strong enough to withstand sustained loading

Bespoke aluminium frame section supplied by Fibrelite to fit exiting rebate – ensuring minimal upheaval to site works

Bespoke Fibrelite covers modified to include apertures accommodating pipework extending from within the trench to above ground networks

Fibrelite covers are corrosion-resistant - unaffected by water, underground gasses and most chemicals

Key Benefits Of KPS Piping For This Project:

Engineered for easy installation. Compact, installer friendly KPS fittings weld both walls of a double wall pipe simultaneously

In house and onsite installation training provided (standard for clients new to the KPS piping system)

Lightweight

Corrosion free polyethylene piping

Zero permeation (liquid/watertight)

Results

The easy access solution provided by Fibrelite trench covers eliminates the need for any specialist personnel or machinery during maintenance or operation, while KPS piping provides a compact, long-term fluid transfer solution (trusted by oil companies around the globe).

Fibrelite And KPS Benefits At A Glance:

Easy manual access to trench services using the ergonomically designed Fibrelite FL7 lifting handles

Best access cover strength to weight ratio available in the market today

Bespoke, made-to-measure

A long-term solution

Fast, simple piping installation

Local technical support

Visit the Fibrelite website for more Fibrelite case studies at www.fibrelite.com

Visit the KPS website for more KPS case studies at www.kpspiping.com

Snaygill Industrial Estate

Keighley Road

Skipton

BD23 2QR

UNITED KINGDOM

01756 799 773