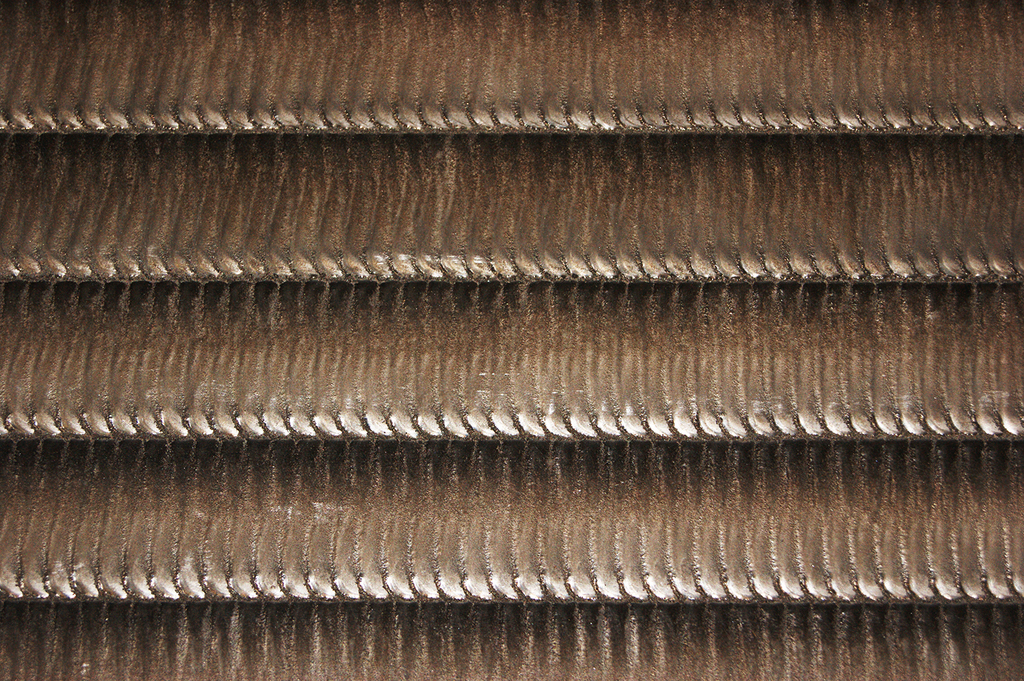

The coating has been developed by the company's engineers who aimed to get a high density of tungsten carbides homogeneously distributed within a nickel-based matrix at high deposition rates. The critical parameters of the process, in particular the temperature, are automatically controlled in order to avoid severe carbide dissolution as it may happen in standard welding techniques.

HD8 is the suitable for applications where standard chromium carbides wearplates are too heavy and not resistant enough, in particular where large production throughput is required.

+41-21 694 11 06stsulpice@messer-castolin.ch