Kelly Rose

Editor

Kelly Rose

Editor

Lloyd Preston provides an overview of the new EN ISO footwear standards.

THE NEW EN ISO footwear standards have now been published after over a decade of use of the existing standards. The new standards are:

EN ISO 20344:2021 Personal protective equipment – test methods for footwear

EN ISO 20345:2022 Personal protective equipment – Safety footwear

EN ISO 20346:2022 Personal protective equipment – Protective footwear

EN ISO 20347:2022 Personal protective equipment – Occupational footwear

At present these are not harmonised for use in the EU or designated in the UK. This means that the norms do not have a presumption of conformity with the regulation (EU) 425/2016. The manufacturer may use these standards with the agreement of the notified/approved body who will apply them as a “product standard” rather than a fully harmonised or designated norm.

During the development process, the standards were specifically revised in such a manner as to not change the state of the art for any of the safety properties included. Certificates issued to the old standards will not be withdrawn on safety grounds… they will remain valid until their natural expiry dates. In fact EN ISO 20344:2011, EN ISO 20345:2011, EN ISO 20346:2014 & EN ISO 20347:2012 remain in the official journal as the harmonised standards with a presumption of conformity to the regulations. These can continue to be used for certification until they are replaced in the Official EU Journal (and the designation list in the UK) the transitions period assigned has expired.

During the first uses of the new EN ISO 20344-7 range of standards, a number of key issues were discovered with the published editions. These are currently addressed by a series of recommendation for use sheets which need to be applied when testing. A decision has been taken to immediately amend the standards. Amendment “A1:2023” has already been written and should be published within the next 12-18 months.

Looking at the EN ISO 20344:2021 and EN ISO 20345, 6 & 7:2022 the main changes are as follows:

Slip resistance – Is now divided into three distinct options:

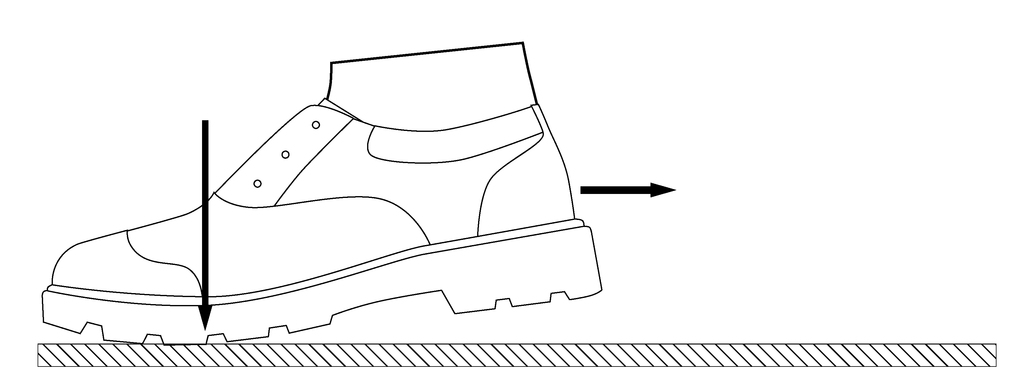

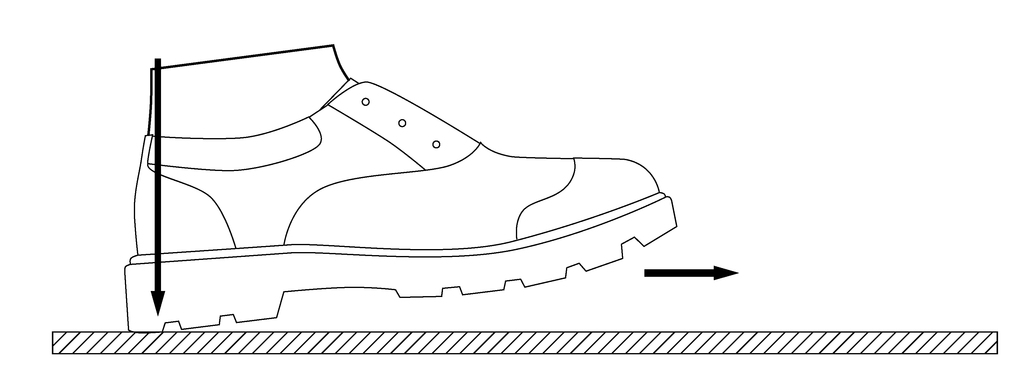

A basic mandatory requirement using a tile surface with Sodium Lauryl sulphate solution lubricant. This is conducted in the heel mode with forward momentum and in the fore part with backwards momentum (The flat test is no longer conducted).

Fig 1. Modes of slip testing

There is also the optional additional category of protection “SR” which may be claimed for work places where non aqueous lubricants may be present. This uses tiles and Glycerol lubricant and test modes forward heel slip and backward forepart slip.

Footwear that designed with spikes or similar additions (for logging, soft loose ground, snow and ice etc) are marked with the “Ø” to indicate that they do not meet the requirements.

Importantly, the requirements have been set at a level that does not change the state of the art of performance. Footwear that complied with the old SRC requirements should also achieve the new SR category of protection.

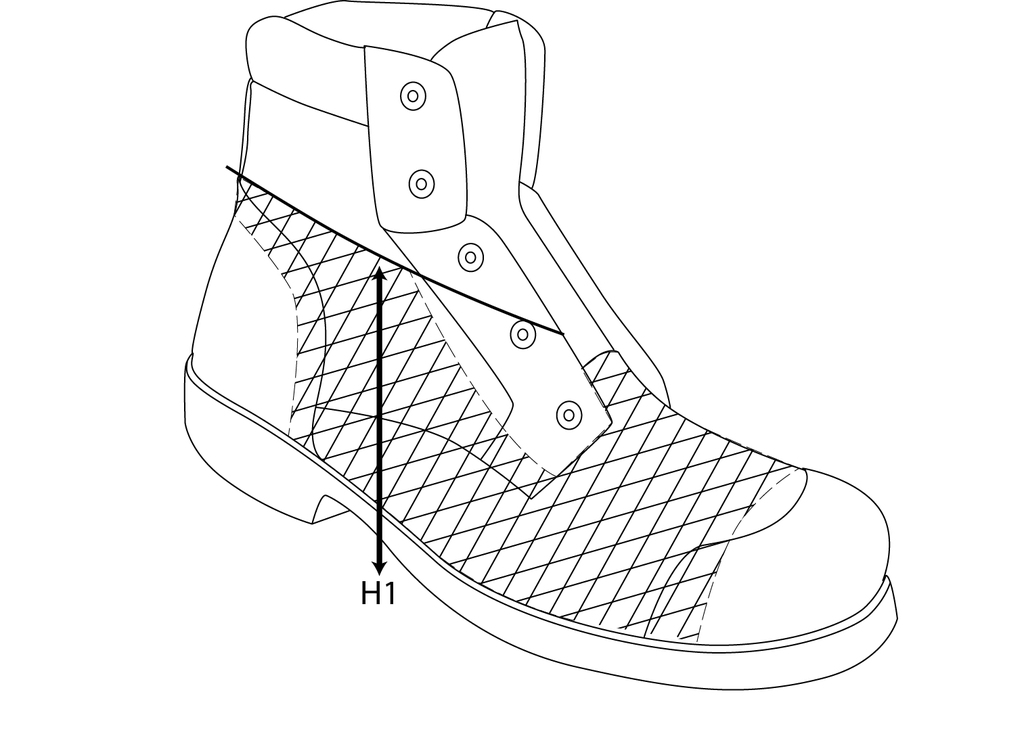

One important change is to the Water vapour permeability and co-efficient requirements. This new norms restricts the area of non-breathable materials permitted in the area defined as “the upper” outside of the counter and toe cap, to no more than 10% “leather” uppers or 25% for more breathable fabric uppers. this was found to be too design and amendment A1:2023 will loosen the requirements of this to 50% by area providing the breathability of the other areas of the upper is 2.0mg/cm2h or more (more than double the minimum requirements for leather 0.8mg/cm2h). Currently the norm is set at 25% by area so users of the norm need to design very carefully around this requirement for the time being.

Fig 2. Area assessment for non-breathable materials

The new category of protection “LG” ladder grip is introduced. Footwear marked “LG” will have a defined pattern with a minimum height of 1.5mm in the waste area and a minimum waist length of 35mm. they also require a 10mm minimum heel breast height with and angle of between 90 & 120◦ from the floor surface. These values are applicable to all footwear sizes, so it is important to measure the smallest size.

The new category of protection “SC” for scuff caps. This can be claimed for product with an overlay material in the toe are offering abrasion resistance. A1:2023 will define an additional design assessment during the ergonomics testing to ensure that the scuff cap prevents ground contact with the upper material during kneeling activities.

The new norm incorporates non-metallic perforation resistance options using the “large” or “small” perforation nail. The resulting marking is “PL” or “PS” respectively. The “PL” method and requirement is identical to the old EN ISO 20344:2011 method providing the all-important continuity and no change in the state of the art. The “PS” test method uses the 3mm test nail, but this really is only intended for very specialist industries where there is a high risk or narrow sharps being present.

There are a number of marking changes in the norms to consider as well

“WRU” (Water resistant upper) changes to “WPA” (Water penetration and Absorption). It was considered that “WRU” implies that whole of the upper is resistant to water penetration when in fact only the material has been assessed.

The group marking S6 & S7 are introduced – this is basically S2 & S3 plus the “WR” water resistant of whole footwear claim. The similar marking is available for protective and occupational footwear as well.

Fuel oil resistance is now an optional test for all product types including the group categories of protection S1, S2, S3 and so on. The test is also amended to include any material exposed on the underside of the sole (whether in ground contact or not).

There are many other small changes to the testing & requirements that may have a minimal effect on the footwear. These include:

An assessment of maximum toe cap flange widths.

A check for broken steel midsoles during the outsole flexing test

A new method of assessment of abrasion of insoles (based on thickness loss)

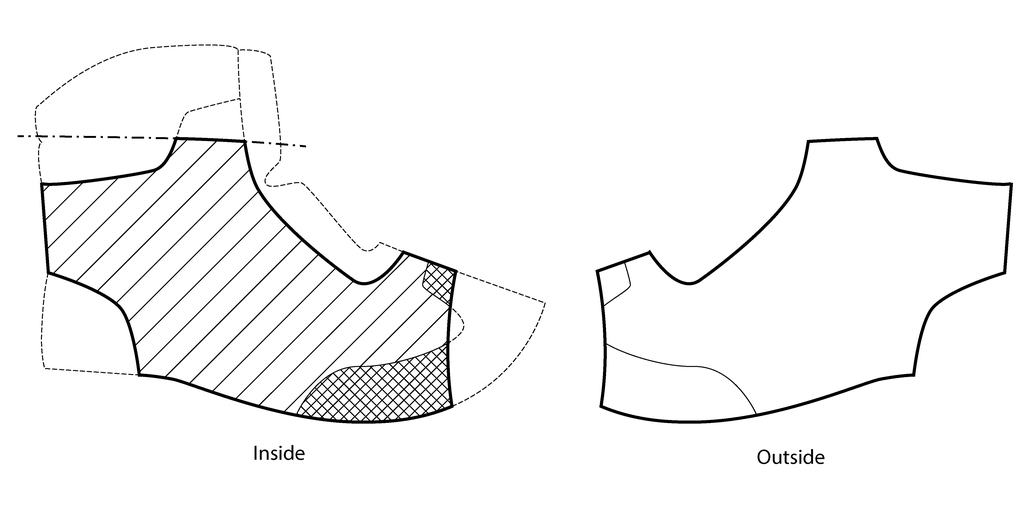

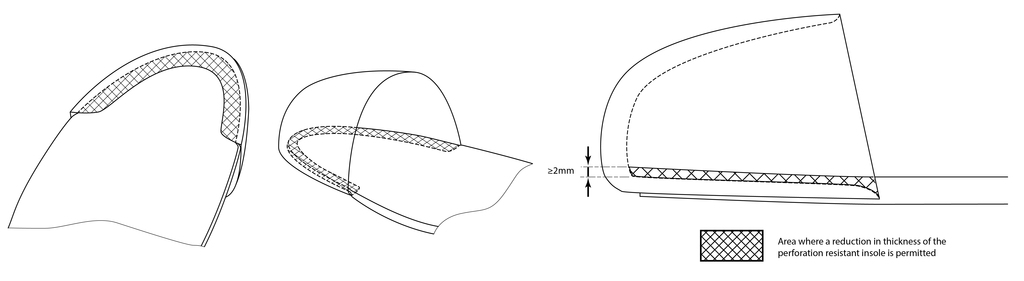

A check that there is no skiving to the edge of non-metallic perforation resistant insoles (expect in the toe cap flange area).

Fig 3. Non-metallic perforation resistant insole skived only in the toe cap flange area.

Clarification of the testing process for Hybrid footwear which now becomes a “classification” with two distinct construction types – those with a pre-moulded foot section and those with a constructed foot section made up of multiple parts.

And so on…

One final but important addition is the introduction of orthopaedic footwear as an annex to the norm. This gives the option for orthopaedic adaption to footwear, from a simple footbed to more complex modifications to the uppers or soles, raises, wedges etc and even bespoke manufactured product. The Annex specifies the sampling and testing protocol for the various types of orthopaedic products that could be made.

Lloyd Preston is technical manager at Tripal. For more information, visit www.tripal.uk

16 Don White Road

Wellingborough

NN8 4FT

UNITED KINGDOM

01933 423 380