Activity in the construction sector is set to rise by more than 7% in 2014, according to figures released by construction industry intelligence specialist Genigan, and with any increase in activity comes an increased risk of accidents and injuries so the construction sector must be more vigilant than ever.

Making compliance appealing

Unfortunately, the statistics surrounding accidents in the workplace aren't enough to make everybody comply with health and safety regulations. While the HSE remains active, and keen to publish a wealth of informative and accurate information, what the industry really needs is for compliance to be made more appealing, and that's where PPE comes in.

Fashionable design

What defines the very best PPE is its ability to do several jobs at once. While the primary job of protective gear is to protect, today's equipment is also known for being incredibly ergonomic. Not only does this make work more comfortable for employees, but it can see a dramatic rise in productivity.

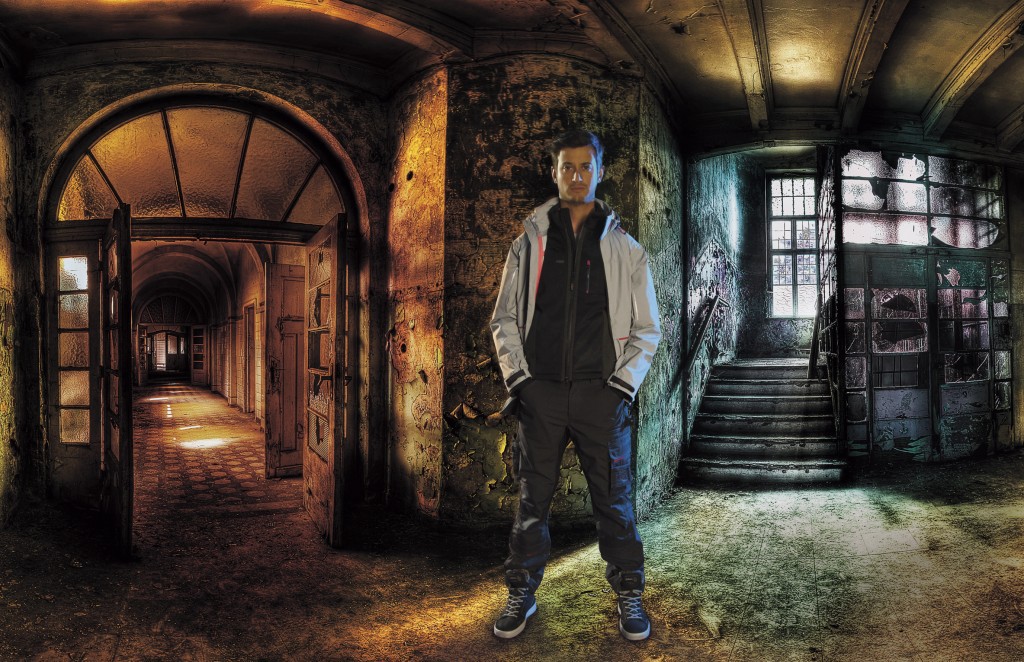

The next step for PPE is into the world of fashion. Fluorescent jackets might not be finding their way onto the catwalks of Paris any time soon, but that doesn't preclude their becoming more stylish. The inclusion of fashion in the design of protective equipment has the potential to transform health and safety compliance in the construction industry.

This is an issue which is particularly relevant for construction sites which are situated in public places. The vast majority of us keep an eye on what we wear when we head into work, and the growth of PPE is allowing construction workers to do the same.

The move towards more fashionable personal protective equipment includes lightweight, wrap around goggles, a greater variety of colour in all clothing, and the potential to include graphic design on safety equipment.

Removing barriers

If we are to increase compliance, the key lies in understanding people's reasons for failing to comply. In other words, the road to full compliance with health and safety regulations requires us to look at the barriers which stand in our way. With over 130 people losing their lives at work last year, and some 78,000 injuries being reported under RIDDOR in 2012/13, it's essential that we get this issue right.

The TUC website highlights a number of issues which employees often run into when using PPE. One of the problems mentioned is the size and fit of certain pieces of protective equipment. High quality PPE should fit well. This is as important from a safety point of view as anything else.

It is clear that construction workers are not only put off by protective equipment which is uncomfortable, but also by equipment which does not look good. In each case, it seems that a major barrier to the use of proper protective gear is the lack of variety.

In fact, a survey by conducted by Kimberly-Clark Professional, a leading provider of hygiene, safety and productivity solutions of attendees at the 2007 National Safety Council (NSC) Congress showed that "unattractive looking" was among the reasons cited for workers failing to wear PPE.

Just as in the high street shops, PPE manufacturers need to be giving workers options. A variety of styles and sizes is as important to the practicality of protective clothing as it is to the aesthetic. Due to the fact that the aesthetics of protective clothing has an impact on its use, it follows that aesthetics have actually become a priority of health and safety officers and equipment manufacturers.

Tony Skelton is founder of Independent UK supplier of health and safety PPE equipment for the workplace, Intersafety.